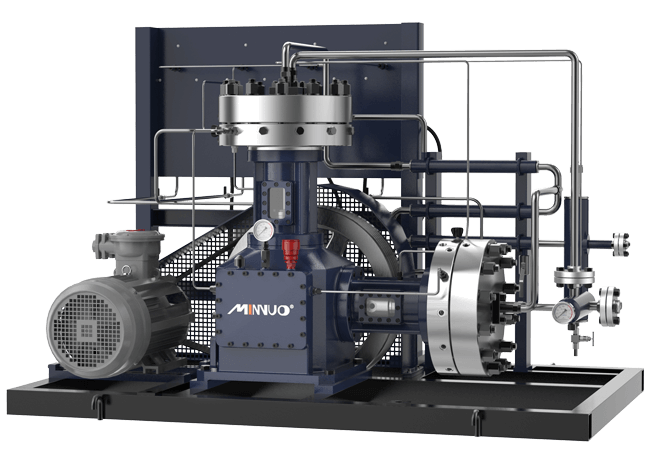

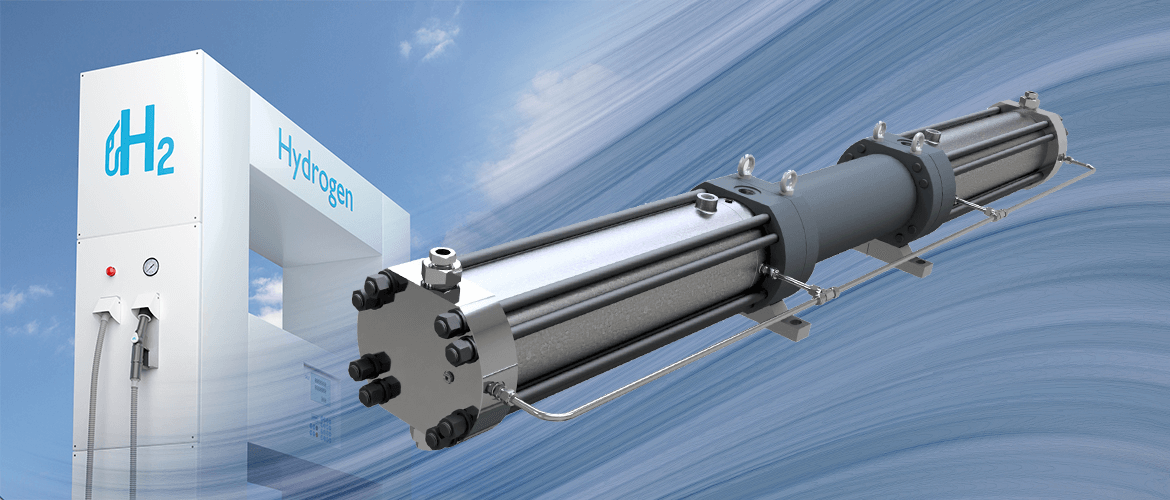

excess of 15,000 psi, so that it can be stored in usable quantities There are several different types of compressors used to compress hydrogen; the more common of these are piston or metal diaphragm compressors. Collectively, they are known as reciprocating compressors. They are the most commonly used commercial hydrogen compressors.

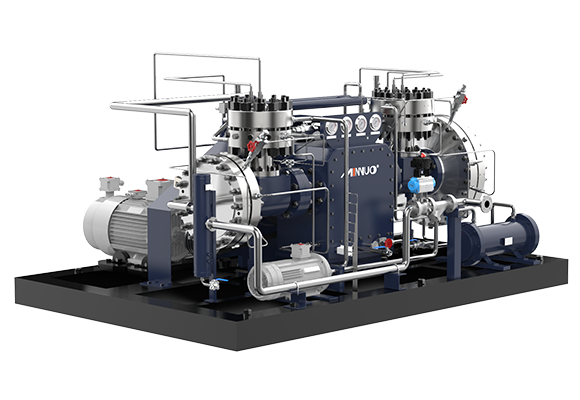

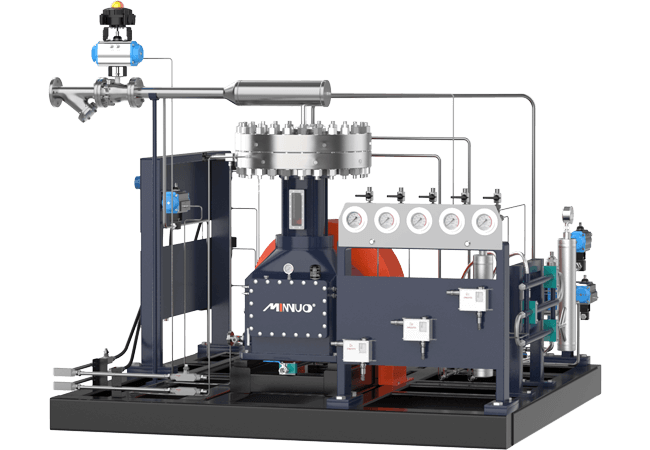

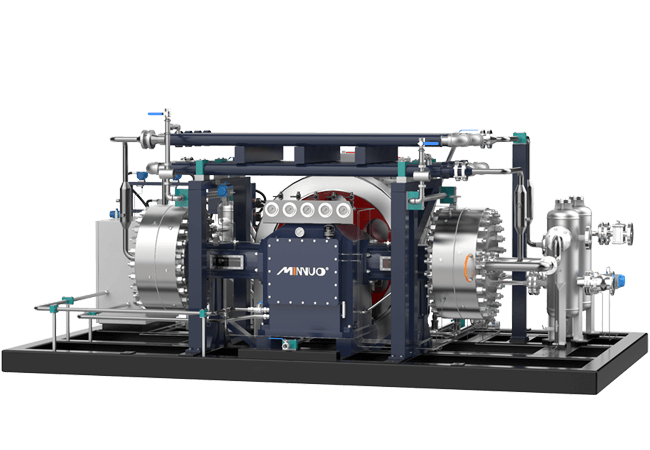

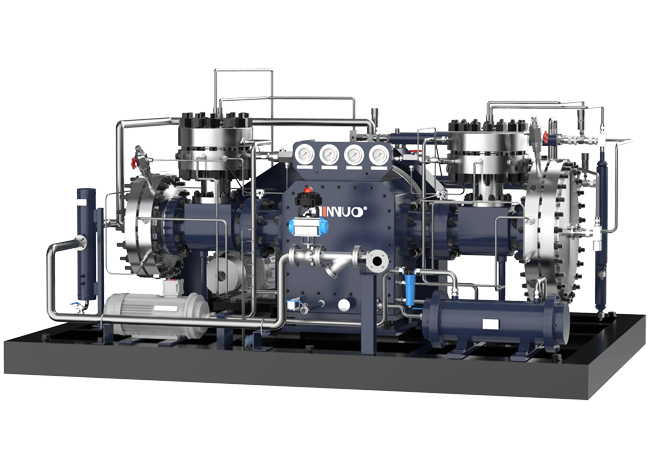

Compressors are required for the transport and storage of hydrogen. Our hydrogen compressors are available in various versions to support the entire hydrogen energy chain:

·hydrogen cracking (methanol, natural gas, gas)

·hydrogen production by water electrolysis

·hydrogen filling

·benzene hydrogenation

·tar hydrogenation

·catalytic cracking

·other hydrogen boosting processes

Working Principle

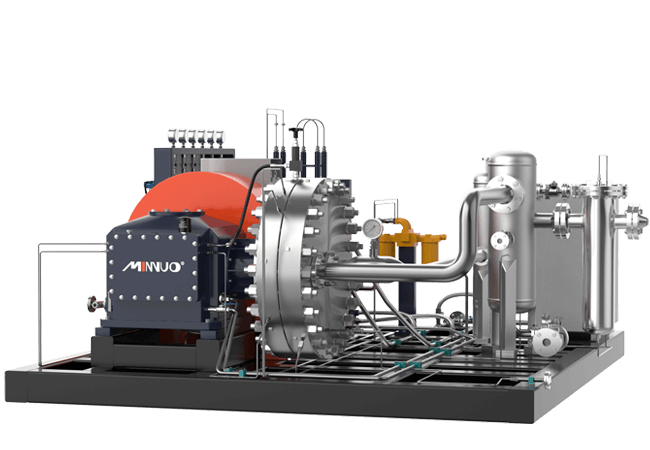

The diaphragm hydrogen compressor is an efficient and safe method for compressing hydrogen gas. A diaphragm compressor is a specially constructed volumetric compressor that uses a rotating diaphragm to compress air or gas. The rotating diaphragm helps to deliver air or gas within the compression chamber and applies the required pressure to deliver gas in the desired area.

Benefits

1.Diaphragm compressor is a special structure of the volume compressor cylinder without lubrication, sealing performance is good, the compression medium does not contact any lubricant, compression process does not produce any pollution, so the compression purity can reach 99.999%. Especially suitable for high-value rare gas and highly corrosive, toxic and harmful, flammable and explosive, radioactive gas compression, transport, and bottling.

2.Diaphragm compressor cylinder heat dissipation, simple and efficient structure, two-stage compression can achieve high pressure, but also close to isothermal compression, therefore, it is widely used in the fields of industrial gas, food and medicine, petrochemical industry, aviation nuclear power, military equipment, scientific research and experiment, etc.

Established in 1987, Min Group has been developing and manufacturing industrial diaphragm gas compressors. They are the preferred equipment for high purity, hermetic gas lift compression for hydrogen fuel stations, chemicals, oil, and gas, etc. We have developed H, D, L, V, and Z models and more than 30 product series for intelligent diaphragm gas compression systems.

We can design and manufacture full instrumentation oil-free reciprocating diaphragm gas compression systems according to customer requirements. Sizes range from 3 hp (2 kW) – 250 hp (186 kW). Output pressures range from 50 psi- 45,000 psi (3,100 bar).