Minnuo Hydrogen is a leading transition solution provider in China towards zero-carbon solutions. The company offers globally recognized alkaline water electrolyzers (ALK) and PEM electrolyzers.

In addition to patented hydrogen electrolyzers, we also provide all-in-one solutions for various hydrogen stations, a diverse range of hydrogen compressors, and hydrogen fuel cells for all kinds of vehicles.

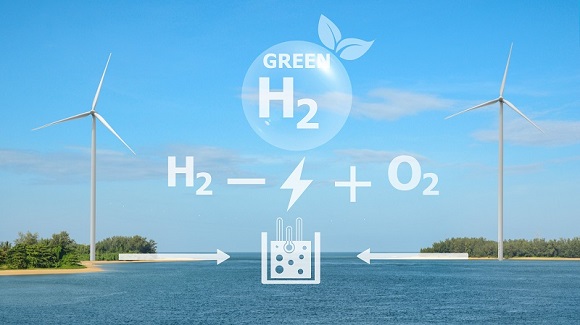

Contact usElectrolytic hydrogen production refers to the process of passing electricity through an electrolyte-filled electrolyzer, causing an electrochemical reaction in water molecules, splitting them into hydrogen and oxygen. This entire process can achieve zero carbon emissions, making it one of the most promising green hydrogen production methods.

The electrolyzer is the core equipment of a water electrolysis hydrogen production system. The performance of the electrolyzer directly affects the efficiency of the entire hydrogen production system. Also, as the amount of hydrogen produced increases, the cost of the electrolyzer represents a larger portion of the total system expenses.

Contact us

Based on different electrolytes, electrolytic hydrogen production can be divided into proton exchange membrane electrolysis (PEM) and alkaline electrolysis (ALK), among others. Alkaline water electrolysis, as the most mature electrolytic hydrogen production technology, occupies a dominant position.

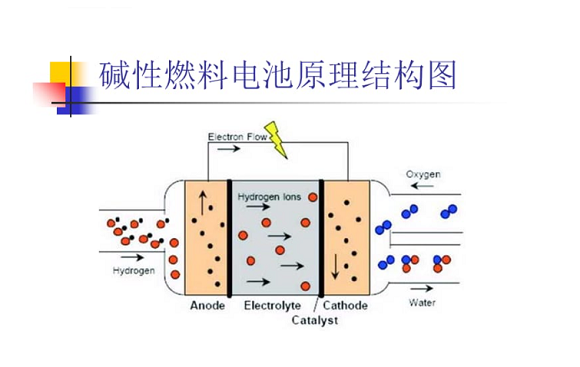

Contact usUsually, an electrolyzer consists of three main parts: the cell, the cathode, and the anode. Its operation principle is as follows: at the cathode, water molecules are split into H+ and OH-, where H+ gains electrons to form hydrogen atoms, which further combine to form hydrogen molecules (H2); meanwhile, OH- traverses through a porous membrane under the influence of the electric field between the cathode and the anode, reaching the anode where it loses electrons, resulting in the generation of a water molecule and oxygen molecule.

The membrane of the electrolyzer is typically made of polymer materials, aiming to prevent the mixing of hydrogen and oxygen gases while allowing ions to move freely within the cell. The cathode and anode are primarily composed of metal alloys, such as Ni-Mo alloys. The electrodes serve as the sites where the electrochemical reactions occur and they determine the efficiency of hydrogen production.

Contact us

Renewable energy-driven electrolytic hydrogen production technology is considered a major contributor to addressing carbon emissions, with alkaline electrolyzers being key components. The cost of alkaline water electrolysis for hydrogen production is influenced by numerous variables, with the most significant factor being the electricity consumption.

The most effective approach to cost reduction is to lower electricity prices or increase operational efficiency. Even as the hydrogen production capacity per unit increases, alkaline electrolysis still holds significant potential for cost reduction.

Contact us